BHQ26 jerin sandbast hukuma ta manual

1.Menene yashi fashewa hukuma

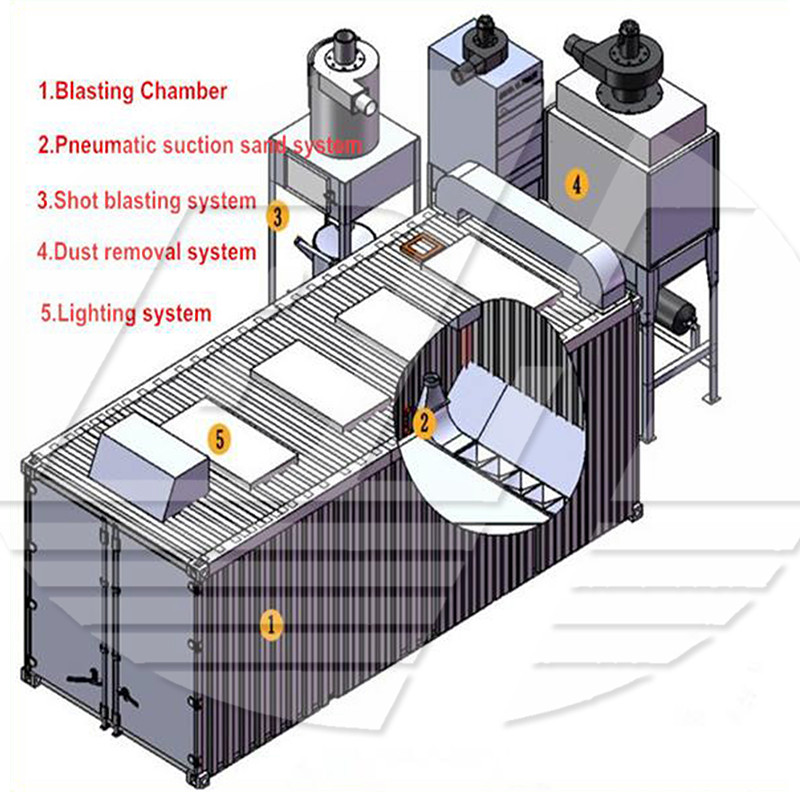

Wasu mutane kuma suna kiran injin fashewar yashi, tankin yashi, fashewar yashi, buɗaɗɗen injin fashewa da sauransu.Sunayen sun bambanta, amma a zahiri suna da ma'ana iri ɗaya.Yana iya aiki daban, amma a mafi yawan lokuta yana aiki tare da dakin fashewar fashewar.

Abun da aka yi na majalisar ministocin yashi ——

Gabaɗaya magana, sassan kamar haka:

1).tanki mai fashewa da yashi:

Kaurin farantin karfe da aka yi amfani da shi don nau'ikan nau'ikan tanki da tushen injin fashewar yashi ya bambanta.Ya fi girma girma, mafi girma da farantin karfe.An ƙayyade wannan musamman ta masana'antar jirgin ruwa bisa ga ainihin halin da ake ciki.

Akwai nau'i biyu na bawul ɗin yashi da bawul ɗin yashi: manual ko pneumatic.Da hannu, wajibi ne don buɗe bawul ɗin yashi da hannu, kuma iskar gas ta buɗe ta atomatik.

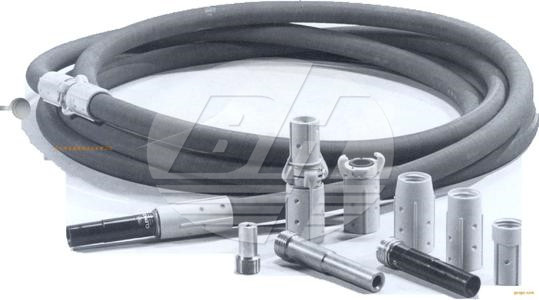

2) bututu mai yashi (misali 10m/20m)

3).Bawul mai aminci

Matsakaicin amfani da tanki mai fashewa gabaɗaya shine 8KG.Matsayin bawul ɗin aminci Lokacin da iskar gas ya wuce 8KG, zai ɓace ta atomatik.Don kare tanki mai fashewa

4) bindiga mai fashewa: Bisa ga kayan, ana iya raba shi zuwa boron carbide, gami da ƙarfe, carbide tungsten, ƙarfe da sauransu.

Mafi ɗorewa shine boron carbide, kuma rayuwar sabis gabaɗaya shine awanni 500-700.

Abu na biyu, rayuwar sabis na tungsten carbide da gami karfe shine gabaɗaya sa'o'i 300-400.

Ana iya amfani da ƙarfe na tsawon sa'o'i 10 kawai, mutane kaɗan ne suka yi amfani da shi.

Tsarin kula da lantarki da sauran abubuwan haɗin gwiwa.

2.Aiki ka'ida na šaukuwa sandblaster

Ka'idar aiki na injin fashewar yashi ya bambanta da na'ura mai fashewa.Na'urar fashewar fashewar harbi tana amfani da ƙarfin tsakiya don yin fashewar harbi.Na'urar fashewar yashi tana aiki da iska mai matsewa kuma tana fesa abrasives (duk yashi na ƙarfe da mara ƙarfe) akan saman kayan aikin.Saboda tasirin matsa lamba, abrasive a cikin tankin yashi ya ratsa ta cikin bawul ɗin yashi da bututun fashewa zuwa bindigar feshi, kuma ana fitar da abrasive a babban saurin, wanda ke canza kayan aikin injiniya na farfajiyar farfajiyar aikin.Saboda tasiri da kuma yanke sakamako na abrasive a kan workpiece surface , Don samun wani mataki na tsabta da kuma daban-daban roughness a kan surface na workpiece, inganta inji Properties na workpiece surface, don haka inganta gajiya juriya na workpiece. ƙara mannewa tsakaninsa da abin rufewa, da kuma tsawaita rufin Dorewa na fim ɗin kuma yana taimakawa wajen daidaitawa da kayan ado na rufin, cire ƙazanta, hayaniya da yadudduka na oxide a saman, yayin da yake roughening surface na matsakaici, haifar da. saura danniya a kan substrate surface da inganta taurin da substrate surface.

3.Main bayani dalla-dalla ga šaukuwa yashi blaster

4. Rashin wutar lantarki na tanki mai fashewa

1).Tsarin tushen iska na injin fashewar yashi gabaɗaya 6m³/min (yawan amfani da iskar bindiga guda ɗaya, idan N ne, saitin tushen iska da ake buƙata shine N*6m³/min.

| Nau'in Abu | Q0250 | Q0250A-Ⅱ | Saukewa: Q0250A-Ⅱ-LX | ||

| Girman cikin tanki (m3) | 0.5 | 0.7 | 0.82 | ||

| Matsin iska (Mpa) | 0.5-0.6 | 0.5-0.6 | 0.5-0.6 | ||

| Adadin da aka fitar (caliber=φ10) (kg/h) | 1800-2280 | 1 gun | 1800-2280 | 1 gun | 1800-2280 |

| 2 bindigogi | 3600-4560 | 2 bindigogi | 3600-4560 | ||

| Amfanin iska (m3/min) | 6.1 | 1 gun | 6.0 | 1 gun | 6.0 |

| 2 bindigogi | 12.0 | 2 bindigogi | 12.0 | ||

| Tsawon bututu mai fashewa (mm) | 7000 | 7000 (2 inji mai kwakwalwa) | 7000 (2 inji mai kwakwalwa) | ||

| Hanyar sarrafawa | Ikon nesa | Ikon nesa | Ikon nesa | ||

| Girma (mm) | 1036*812*1860 | 1120*900*1890 | 1086*812*2060 | ||

| Nauyi (kg) | 396 | 500 | 690 | ||

2).Matsakaicin iska da injin fashewar yashi ke buƙata shine 0.5-0.6mpa (idan matsa lamba ya yi ƙasa sosai, fashewar yashi zai yi rauni kuma tasirin tsaftacewa zai shafi).

3).Adadin yashi mai fashewa / harbe-harbe a cikin awa daya na injin fashewar yashi shine 1800-2100 kg.

4) Aikace-aikacen kewayon sandblasting

a.Pre-jiyya: duk abubuwan da ake amfani da su na fashewa kafin a rufe su, irin su electroplating, zanen, spraying, da dai sauransu, saman yana da cikakkiyar tsabta, kuma a lokaci guda yana inganta haɓakar mannewa da juriya na suturar sutura.

b.Pre-jiyya kafin tsaftace saman sassa: descaling, saura da datti na karfe sassa kamar simintin gyaran kafa, stamping sassa, waldi sassa, zafi magani sassa;share fage na samfuran da ba na ƙarfe ba, cire tabo baƙar fata a saman fakitin yumbu da raguwar ƙirar fenti, da dai sauransu.

c.Gyaran tsofaffin sassa: gyarawa da tsaftace duk sassan motsi kamar motoci, babura, kayan aikin lantarki, da dai sauransu. A lokaci guda kuma kawar da gajiyar gajiya da tsawaita rayuwar sabis.

d.Gama aiki a kan saman workpiece: duk karfe kayayyakin da wadanda ba karfe kayayyakin (filastik, crystal, gilashin, da dai sauransu) surface burbushi an shafe, da kuma argon hazo surface jiyya sa samfurin surface hažaka.

e.Mold jiyya: Argon haske hazo surface jiyya na mold surface, mai hoto samarwa, da kuma mold tsaftacewa, ba don lalata mold surface, don tabbatar da daidaito na mold.

f.Maganin Burr: Ana cire sassan injinan tare da ƙananan bursu, kuma an kawar da sassan filastik na sassan allura.

g.Sake yin aiki da samfuran da ba a so: kawar da murfin samfurin da ba a so, kawar da canza launin da ba a so a saman da kuma cire bugu.

h.Ƙarfafawa: ƙara taurin sassa na ƙarfe da kuma kawar da damuwa, kamar maganin saman saman jirgin sama, maɓuɓɓugan ruwa, kayan aikin inji da makamai.

i.Etching da anti-skid sarrafa: etching alamu, rubutu da anti-skid magani a saman na karfe kayayyakin da wadanda ba karfe, kamar: marmara, anti-skid handling, seal, stele haruffa, da dai sauransu.

j.Maganin tufafin denim: Tufafin denim yana da matte, farar fata da tasirin wisker cat.

5.A abũbuwan amfãni daga sandblast hukuma:

1).Sassan ƙarfe na injin fashewar yashi ba su lalace ba, kuma daidaiton girman ba zai canza ba;

2).Fuskar sashin ba a gurɓatacce ba, kuma abrasive ba zai amsa sinadarai tare da kayan ɓangaren ba;

3).Na'urar fashewar yashi na iya sauƙin sarrafa sassan da ba za a iya isa ba kamar su gungun kogo, kuma ana iya zaɓar nau'ikan abrasives iri-iri don amfani;

4).Farashin sarrafawa yana raguwa sosai, galibi ana nunawa a cikin haɓaka ingantaccen aikin injin fashewar sandblasting, wanda zai iya biyan buƙatun kammala saman daban-daban;

5).Ƙananan amfani da makamashi da ƙananan farashi;

6).Na'urar fashewar yashi baya gurbata yanayi, yana kawar da farashin kula da muhalli;